- +91 98719 60077

- +91 98102 84172

Menu

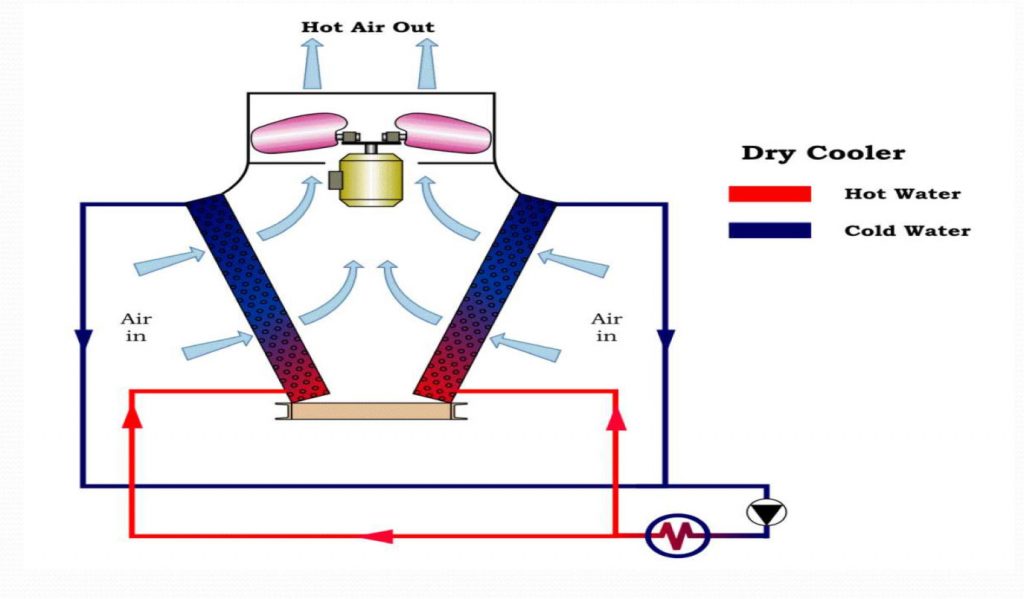

ACFC is an air-cooled heat exchanger wherein any type of fluid can be cooled with ambient air. The design criteria are to cool process water or fluid in the tubes to about 5o°C approach of ambient dry bulb temperature.

Dry Coolers are custom design for any flow rate and Corresponding temperature difference as per process requirement. Technology can be applied for: engine cooling, Turbine auxiliary cooling, turbine inlet air cooling, and process cooling.

CCPL provides an air-cooled heat exchanger, which rejects heat from a process cooling medium to the surrounding atmosphere by means of dry cooling i.e. convective heat transfer. The operating mode is dependent mainly upon the heat load and ambient conditions.

The process cooling medium generally water or a water glycol mixture, flows inside the horizontal tubes of finned tube heat exchanger bundles arranged in a W-shape or horizontal configuration. Each cooler has a design ambient threshold temperature (typically 45 – 50 °C Dry Bulb Temperatures).

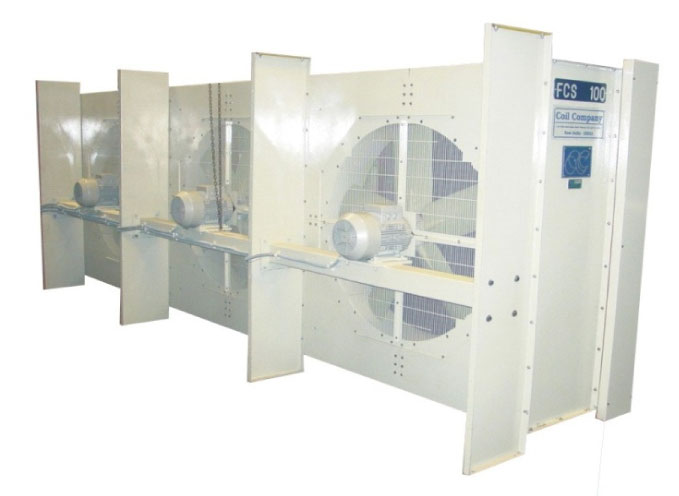

Coil:

1. Tubes : 5/8” OD Copper / Aluminum / Stainless Steel / Mild Steel

2. Fins : Aluminum / Copper

3. Headers : Copper / Aluminum / Stainless Steel

4. Casing : Galvanized Iron Sheet

Housing: Powder Coated Galvanized Iron Sheet

Base Frame: Support Structure for Coils made of MS Channels

Axial Flow Impellers: For Suction of air across the coils (Multi-Wing – Denmark)

Motors: 3Ф Squirrel cage induction motors for driving the axial flow impellers (Siemens / Crompton Greaves / ABB)

We are proud to introduce ourselves as a Coil Company Pvt. Ltd., HVAC Company since 1984, established as a joint venture company with Coil Company Inc. PA, U.S.A.